A Ceramic Cup is a unique blend of art and utility. These cups are often celebrated for their durability and aesthetic appeal. Made from clay, they undergo a fascinating transformation during the making process.

Creating a Ceramic Cup begins with selecting the right clay. This step is crucial, as it influences the cup's texture and strength. The clay is then shaped, often by hand or on a potter's wheel. This phase allows for creativity and a personal touch. The true magic happens during firing. The cup is heated at high temperatures, turning the soft clay into a hard, usable form.

After the initial firing, glazing is applied. This gives the cup its desired color and finish. However, not all designs are perfect. Some may have imperfections, which can tell a story or reflect a craftsmanship journey. Each Ceramic Cup embodies uniqueness, blending art with everyday life.

Ceramic cups are universally appreciated for their durability and aesthetic appeal. Made from clay, these cups undergo a meticulous process of shaping and firing. Traditionally, artisans start by mixing clay with water to form a malleable lump. The clay is then hand-formed or wheel-thrown into the desired cup shape. This process often reveals each artisan's unique touch, making every piece distinctive.

The firing stage is crucial. The shaped cups are heated in a kiln at high temperatures. This transforms the clay into a sturdy ceramic. After the initial firing, cups can be glazed. This adds color and makes them easier to clean. However, not every glaze is perfect. Some may show imperfections. These quirks can tell a story about the cup’s journey from raw material to finished product.

Ceramic cups maintain heat well. They can have vibrant designs or simple, plain surfaces. The texture can vary, from smooth to slightly gritty. Some ceramic cups might even develop tiny cracks over time, adding to their charm. Owning a ceramic cup is about appreciating both function and artistry. It encourages reflection on the craft and the imperfections that come with it.

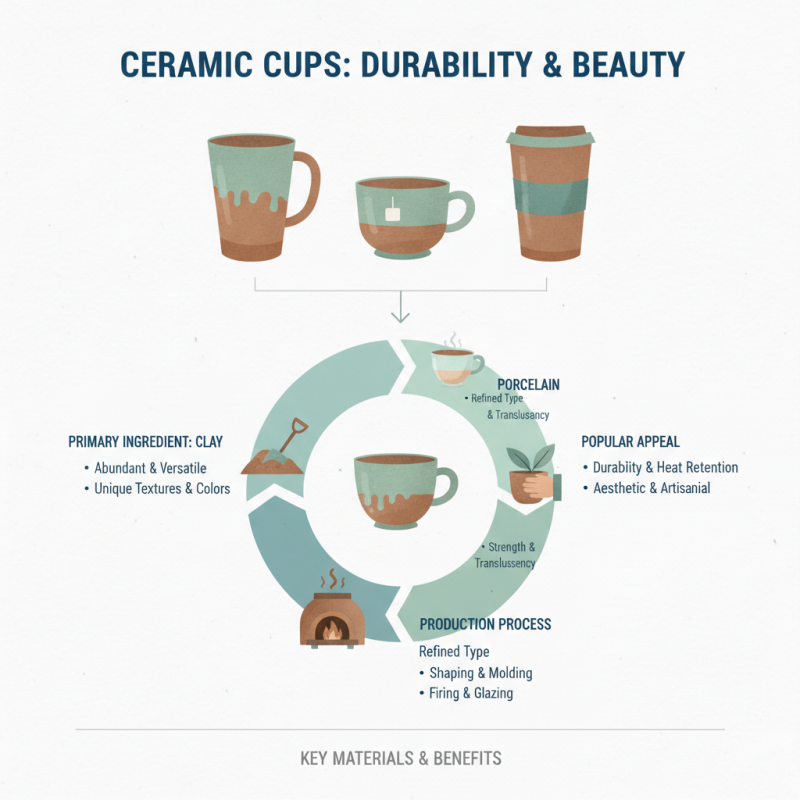

Ceramic cups are popular due to their durability and aesthetic appeal. The production of these cups involves several key materials. The primary ingredient is clay, which is abundant and versatile. Different types of clay offer unique textures and colors, influencing the final product. Porcelain is a refined type of clay, known for its strength and translucence.

Another essential material is feldspar. This mineral acts as a flux and helps lower the melting point of the mixture. It contributes to the cup's strength and enhances its glossy finish. Adding silica further improves the structure of the ceramic. This combination of materials plays a crucial role in the final quality of the ceramic cup.

Tips: When selecting ceramic cups, consider their weight and texture. Heavier cups often feel more luxurious but may be fragile. Note the finish; a glossy surface is easier to clean but can show stains more readily. Also, inspect for imperfections. Small blemishes can add character but may affect durability. Always reflect on how materials shape the cup’s functionality and look.

Making a ceramic cup is an art form that combines creativity and craftsmanship. The process begins with selecting the right clay. You can choose earthenware, stoneware, or porcelain. Each type has unique characteristics and can affect the final piece's durability and aesthetics.

The clay is then wedged to remove air bubbles. This step is crucial. Air pockets can cause cracks during firing. After wedging, the clay is shaped. Potters typically use a potter's wheel, but hand-building techniques are also popular. It’s important to ensure uniform thickness to avoid weak spots.

Drying the shaped cup is essential. The cup must dry slowly and evenly. This prevents warping and cracking. Once it's leather-hard, finer details can be added. Decorations, textures, or handles can be carved in at this stage.

Tips: Always keep your workspace clean. A cluttered area can lead to inconsistencies in your work. Also, don’t rush the drying process. Patience plays a vital role in creating a perfect cup.

The next step is bisque firing. This process hardens the cup, preparing it for glazing. Once cooled, a glaze is applied. This not only enhances the appearance but also makes the cup functional. The final firing brings everything together, sealing the glaze and resulting in a beautiful ceramic piece.

Mistakes can happen. A world of possibilities exists, and not every attempt will be perfect. Reflect on what went wrong to improve in your next creation. Embrace the imperfections, as they often add character.

Finishing techniques for ceramic cups play a crucial role in defining their aesthetics and functionality. One common method is glazing, which not only enhances the appearance but also makes the cup waterproof. According to industry reports, around 80% of ceramic pieces use some form of glaze. These glazes can be matte or glossy, with colors ranging from vibrant hues to soft pastels. The choice of glaze affects both the visual appeal and user experience.

Another key technique is polishing. While some artisans prefer a rustic finish, others opt for a smooth, refined surface. Polishing requires skill and time. It can reveal imperfections, creating a unique character for each cup. Reports indicate that 65% of consumers appreciate handmade cups for their distinct flaws and variations. This embraces the idea that imperfection often tells a better story.

Additionally, decals and paintings add individual flair. Skilled artists apply these decorative elements by hand. This process can introduce inconsistencies, leading to unexpected yet charming outcomes. Traditional methods often clash with modern techniques, creating an intriguing blend of styles. Ultimately, the finishing techniques for ceramic cups transform simple clay into captivating art pieces.

Ceramic cups are versatile and widely used in everyday life. Their ability to retain heat makes them ideal for coffee and tea. In 2020, the global ceramic cup market was valued at approximately $10 billion. This indicates a steady demand for these items, especially among cafes and restaurants. Their aesthetic appeal also plays a significant role. Many consumers prefer handmade designs for their unique character.

The applications of ceramic cups extend beyond the kitchen. They are often used in art and design, serving as unique gifts or home decor. Some artists create intricate patterns, blending functionality with creativity. However, not all ceramic cups are environmentally friendly. Many processes involve significant energy use and raw material extraction. This raises questions about sustainability in production.

Moreover, ceramic cups can be prone to chipping and cracking. While they offer a classic look, durability varies with quality. Consumers often must balance aesthetics with practical use. Despite their charm, these products require mindful purchasing. Social awareness in selecting ceramic items can foster better production practices.